Cultivated Meat

The cultivated meat research ecosystem has developed rapidly in recent years. Several companies and research groups worldwide are in a race to bring meat cultivation to an industrial scale and to the consumer’s plate.

What is Cultivated Meat?

Firstly requires an understanding that cultivated meat is real meat, just like conventional meat. It is formed by the same types of cells arranged in the three-dimensional structure of animal muscle tissue. Therefore, it can replicate the sensory and nutritional profile of meat that the consumer is already familiar with. The difference is in production, which takes place in bioreactors in a factory environment, without the need to raise or slaughter animals.

This change in the production process solves several conventional production chain problems, such as reducing land use, water consumption, and CO2 emissions and eliminating antibiotics and other veterinary products to treat animals. Cultured meat is free of non-edible components, reducing production time and the number of nutrients needed to produce each kilogram.

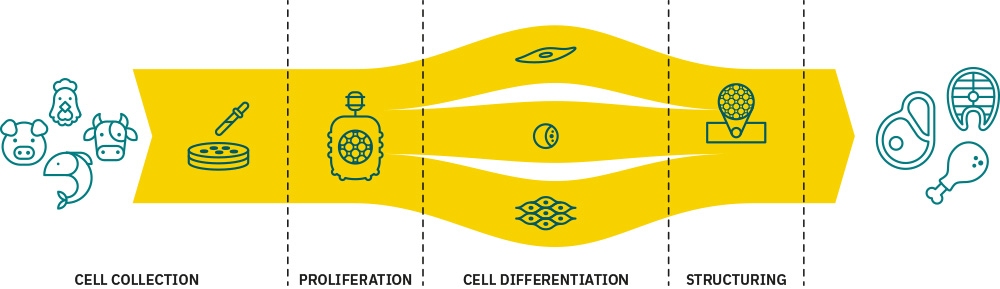

Cultivated meat production steps

The production of cultivated meat is a complex multidisciplinary process, which takes place in four stages: a collection of cells, proliferation in bioreactors, cell differentiation into myofibers, adipocytes, or other cell types, and structuring on scaffolds.

Source: Porto & Berti (2022)

After this process, the cultivated meat is collected for processing into meat products such as hamburgers, breaded products, meatballs, or even whole cuts such as steaks, chicken pieces, fish fillets, and seafood.

Characteristics of the cultivated meat production process:

Cell Lines

This is when cells collected from animal tissues are isolated – usually stem cells. They then multiply in in vitro systems and later differentiate into the mature cells that make up the meat.

Two main types of cells can be used: primary ones, whose culture is established directly from animal tissues, and cell lines, adapted to be maintained for long periods in culture and, therefore, can be subcultured several times. The cells are selected, validated, and frozen in small batches, allowing gradual use over time without needing new collections.

Culture Media

After being collected, the cells are isolated and cultivated in an appropriate culture medium. The composition of the medium plays a fundamental role in the cultivated meat production process since it can influence essential factors such as growth efficiency and final product characteristics. The composition of the medium can also impact final meat characteristics, such as muscle cell degeneration or making the meat more opaque.

Bioreactors

One of the significant challenges in the cell culture system is industrial production. For this to be possible, the cultivation process on an industrial scale must take place in bioreactors. Bioreactors allow the process to be automated, planned, and suitable for each cell type, reducing human manipulation and contamination risks. These tools enable maintaining a controlled environment to standardize the industrial process.

Structuring

Keeping the cells aligned in the form of fibers during the growth process is a significant challenge in the cell culture process – which occurs naturally in conventional meat and the formation of structured tissue. Various solutions, such as scaffolds and microcarriers, are being explored to address this issue in cultivated meat production.

These systems provide mechanical support, porosity for nutrient exchange, and structure and texture more similar to conventional meat. To support structuring, several synthetic or natural biomaterials have been used in tissue bioengineering. Examples include collagen, cellulose, decellularized spinach leaf, and textured soy.

Final product and its processing

After the cell culture process is complete, the cultivated meat is collected for use as fresh meat – ground beef, steaks, chicken pieces, fish fillets, etc. – or it can be used as a raw material in the production of various meat products such as hamburgers, breaded products, meatballs, sausages, among others. Like conventional meat, products resulting from cell culture must undergo quality control and inspection and have their nutritional composition informed on the label.

Deepen your knowledge of the science of cultivated meat

GFI Brazil, in partnership with the Institute of Food Technology (Ital), brings in this issue a comprehensive bibliographic review of cell culture technology for obtaining proteins. Initially, the production process’s main technical characteristics are presented, including cell lines, culture media, culture structure, and equipment (bioreactors).